From sewing machines electronics without operator involvement

Works on any brand, any year of manufacturing, any technology

Cutting - Sewing - Washing / Printing - Quality Control - Packing

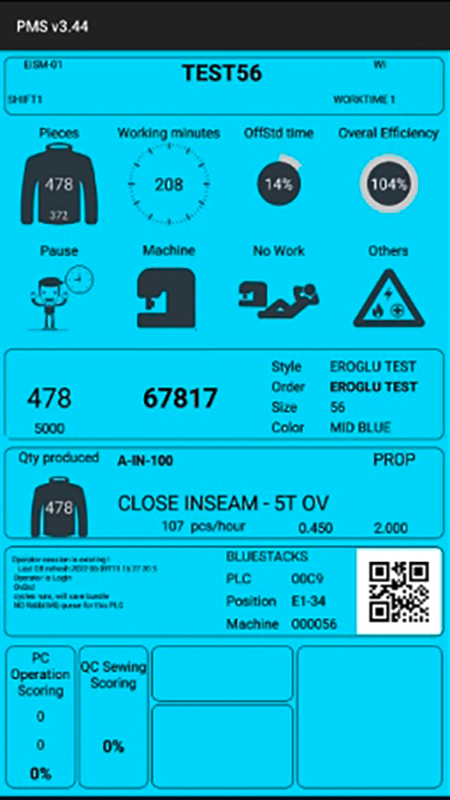

Counts all pieces executed by each operator, each operation, each line

Monitors in REAL-TIME the evolution of orders

Gives stock control inventory of an order

Calculates Operator efficiency, Line efficiency, Factory efficiency

Calculates LOST TIME and breaks it down based on reasons: Operator, Machine breakdown, Line Balancing, Others

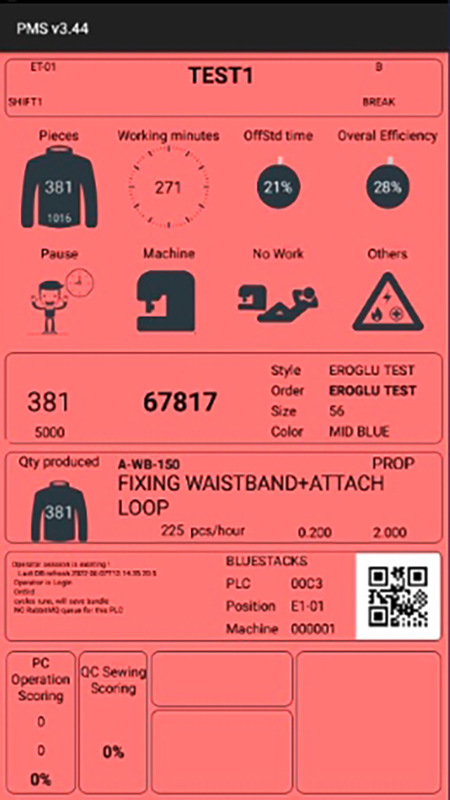

Provides detailed performance information to operators

Tablet display background color changes according to Operator Efficiency

Automatic training by delivering sewing operations videos directly on tablets

SIZE CHARTS and sewing parameters (rpm, spi, thread & needle types)

Salaries and bonuses are delivered on tablets

API integration with existing ERP

Getting data’s and pushing back data into ERP

Android apps allowing accessing reports from tablets or smartphones

DATA CONTROL IS POWER ! Enter in DIGITAL WORLD OF APPAREL MANUFACTURING, embrace INDUSTRY 4.0

Existing applications available to PMS IoT create a complete INDUSTRY 4.0 package

Complete digital Sewing Training application to manage your workforce training. Sewing operation methods videos are available on tablets; OPERATOR MATRIX SKILLS covering past 12 months; IE Training schedule for each operation

Direct interaction with workers on HR topics. Calculation and display on tablets of salaries and bonuses

Monitor mechanics activity, register all spare parts usage and generate reports over machine maintenance costs and spare parts consumption

Following all sewing defects by tracking the operators who generate it. Measurements are made digitally and loaded into the tablets using BAGEL – DIGITAL MEASURING SYSTEMS

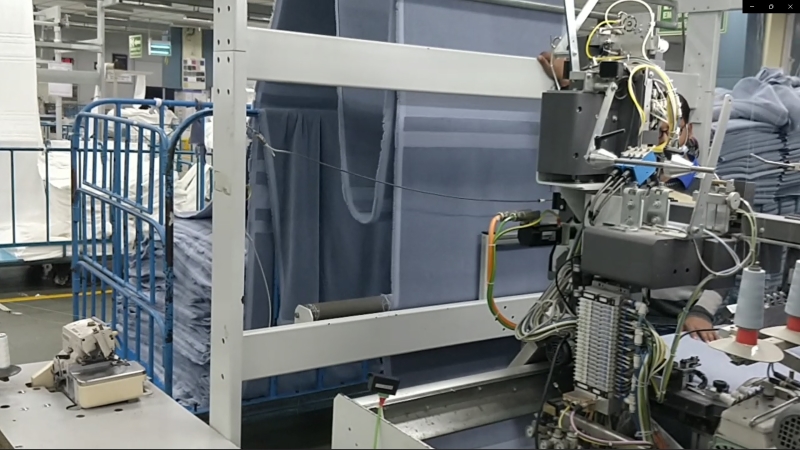

We are “scanning” the Sewing Machine activity either by connecting our software directly with the electronic of the machines (in case of new generation of machines) or through a special hardware able to “read” the machine activity

PMS IoT works on any kind of sewing machine, any brand, any age (from 20 years old machines to last generations) and any type of garmenting operation (sewing, ironing, Quality Control, manual operations)

Centralized server, process all data and create analysis. Calculate ON STANDARD EFFICIENCY, OVERALL EFICIENCY, MACHINE BREAKDOWN TIME, TOTAL QTY PRODUCED, for each operator, each line and each factory; all calculations are refreshed every minute

Android tablets connected to each machines are the interface between operators and PMS IoT software. Tablets display REAL-TIME data - OVERALL EFFICIENCY, QTY PRODUCED, QUALITY

Mounted TV SCREENS on each line are displaying line specific KPI'S. LINE BALANCING identifying bottleneck operations; LOW EFFICIENT OPERATORS are listed; OFF STANDARD TIME is displayed in REAL-TIME, QUALITY ASSURANCE performance is calculated

Coloured tablet display create awareness to operators over their performance. REAL-TIME LINE BALANCING with coloured operation bars creates awareness for Line Supervisors for the line bottlenecks. REAL-TIME OFF STANDARD TIME create awareness over the LOST TIME